Exploring the anti-corrosion centrifugal fan: the "anti-corrosion guardian" of the industry

Exploring the Anti-Corrosion Centrifugal Fan: The "Anti-Corrosion Guardian" of the Industry

Exploring the Anti-Corrosion Centrifugal Fan: The "Anti-Corrosion Guardian" of the Industry

In various industrial applications, the need for reliable and durable equipment is paramount. Among these, centrifugal fans play a crucial role in ventilation, cooling, and material handling processes. However, one of the significant challenges faced by industries is corrosion, which can lead to equipment failure and increased maintenance costs. Enter the anti-corrosion centrifugal fan, often referred to as the "anti-corrosion guardian" of the industry. This article explores the importance, design, and applications of these fans, highlighting their role in enhancing operational efficiency and longevity.

Understanding Corrosion in Industrial Applications

Corrosion is a natural process that occurs when materials, particularly metals, react with their environment. In industrial settings, factors such as humidity, temperature fluctuations, and exposure to corrosive substances can accelerate this process. For centrifugal fans, which are often used in harsh environments, corrosion can severely compromise their structural integrity and performance.

The costs associated with corrosion are staggering, with estimates suggesting that it can account for billions of dollars in losses annually across various industries. These losses stem from equipment failure, production downtime, and the expenses related to repairs and replacements. Therefore, the development of anti-corrosion solutions is essential for maintaining operational efficiency and reducing long-term costs.

The Role of Anti-Corrosion Centrifugal Fans

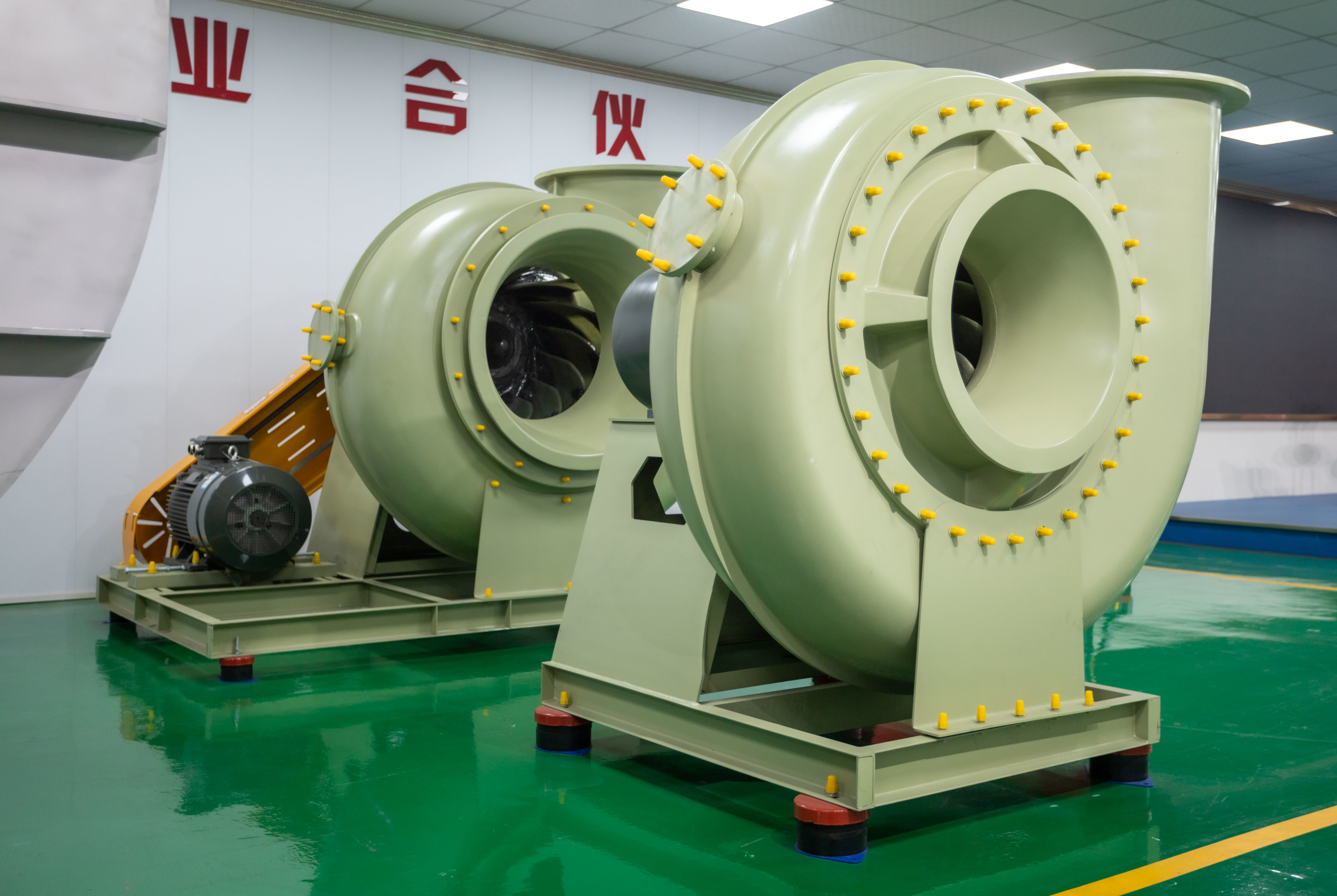

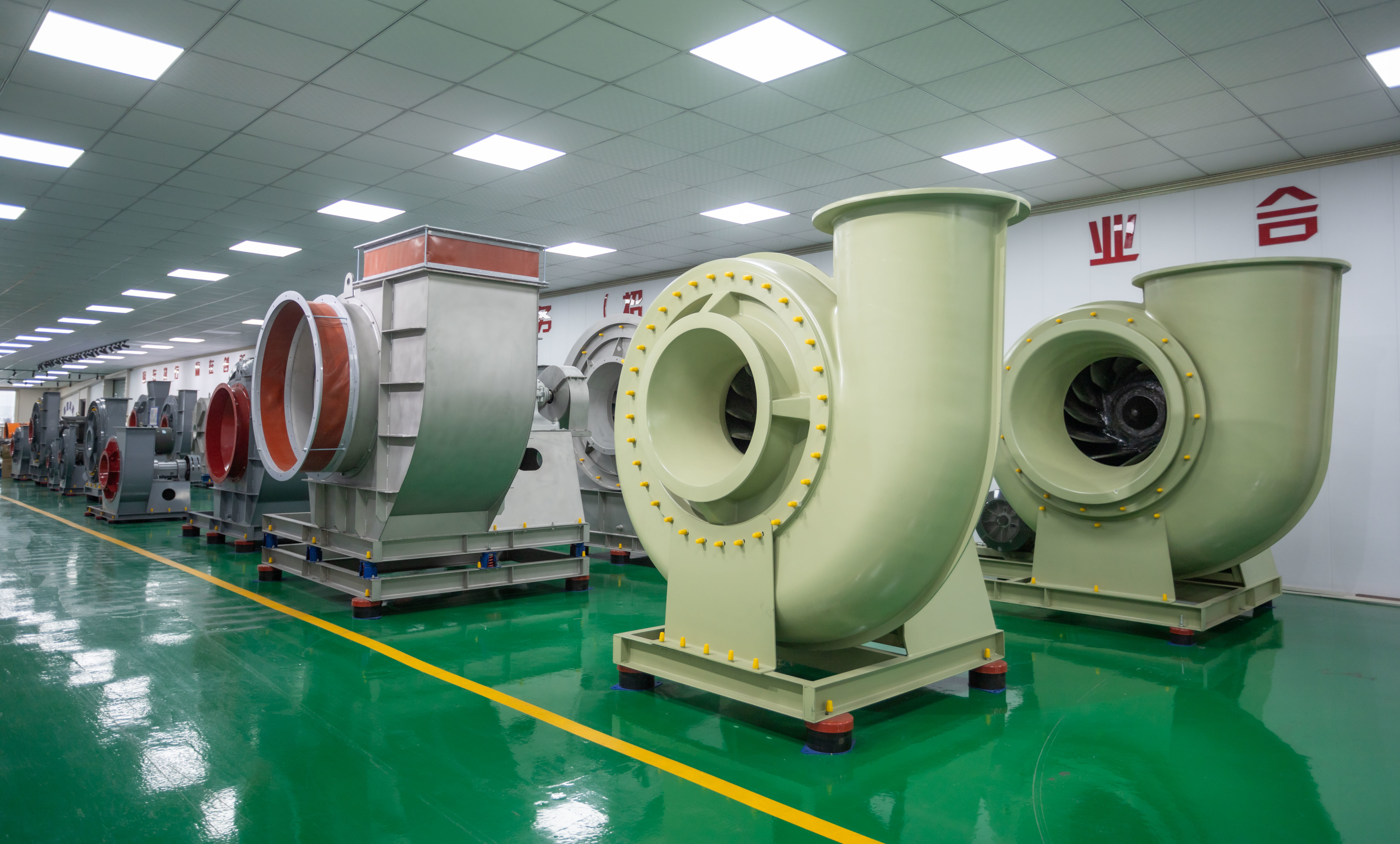

Anti-corrosion centrifugal fans are specifically designed to withstand harsh environments where traditional fans might falter. These fans are constructed using materials and coatings that provide resistance to corrosive elements. Common materials include stainless steel, fiberglass, and specialized coatings that protect against chemical reactions and moisture.

The primary role of these fans is to ensure effective air movement while minimizing the risk of corrosion. By employing advanced materials and innovative design techniques, manufacturers can create fans that not only meet performance standards but also offer enhanced durability. This capability is especially crucial in industries such as chemical processing, wastewater treatment, and mining, where exposure to corrosive substances is prevalent.

Design Features of Anti-Corrosion Centrifugal Fans

The design of anti-corrosion centrifugal fans incorporates several key features aimed at maximizing their lifespan and performance.

Firstly, the choice of materials is critical. Stainless steel and aluminum are commonly used for their inherent resistance to rust and corrosion. Additionally, many manufacturers apply specialized coatings that create a barrier against moisture and chemicals, further enhancing durability.

Secondly, the design of the fan blades is essential for optimal airflow and efficiency. Anti-corrosion centrifugal fans often feature blades that are engineered to minimize turbulence and reduce wear and tear. This design not only improves performance but also contributes to energy efficiency, which is a vital consideration for industries seeking to reduce operational costs.

Finally, the installation and maintenance of these fans play a crucial role in their effectiveness. Proper installation ensures that the fan operates within its intended parameters, while regular maintenance helps identify potential issues before they escalate into significant problems. Manufacturers often provide guidelines and support for installation and maintenance to ensure that their products function optimally.

Applications Across Industries

The applications of anti-corrosion centrifugal fans are vast and varied.

In the chemical processing industry, these fans are essential for ventilating hazardous fumes and ensuring a safe working environment. The corrosive nature of many chemicals necessitates the use of robust ventilation solutions that can withstand constant exposure to harsh substances.

Similarly, in wastewater treatment facilities, anti-corrosion fans are vital for aerating and ventilating water treatment processes. The presence of corrosive agents in wastewater can lead to rapid deterioration of standard equipment, making anti-corrosion solutions imperative for maintaining efficiency and safety.

The mining industry also benefits significantly from anti-corrosion centrifugal fans. In environments where dust and moisture are prevalent, these fans ensure proper ventilation and dust control, thereby enhancing worker safety and equipment longevity.

The Future of Anti-Corrosion Centrifugal Fans

As industries continue to evolve, the demand for advanced anti-corrosion solutions will only increase. Manufacturers are investing in research and development to create even more resilient and efficient centrifugal fans. Innovations in materials science, such as the development of new alloys and coatings, promise to further enhance the durability of these fans.

Moreover, as sustainability becomes a focal point for many industries, energy-efficient designs will be paramount. Anti-corrosion centrifugal fans that offer both durability and energy savings will play a critical role in helping industries meet their environmental goals.

Conclusion

The anti-corrosion centrifugal fan is truly the "anti-corrosion guardian" of the industry. By providing reliable and durable solutions for ventilation and cooling, these fans help mitigate the risks associated with corrosion, ultimately leading to enhanced operational efficiency and reduced maintenance costs. As industries continue to face challenges related to harsh environments, the importance of these specialized fans will only grow. Investing in anti-corrosion technology is not merely a choice; it is a necessity for businesses aiming to thrive in a competitive landscape.

Tag: