Factory Mechanical Automation Welding Technology: Leading the Wave of Industrial Welding in the New Era

In recent years, the industrial landscape has undergone significant transformations, driven largely by technological advancements. One of the most notable changes has been the rise of factory mechanical automation, particularly in the field of welding technology. This article explores the evolution of welding processes, the benefits of automation, and the future prospects of this vital industry.

The history of welding dates back to ancient times when blacksmiths used rudimentary techniques to join metal pieces. However, it was not until the 19th century that welding began to evolve into a more sophisticated practice with the advent of electric arc welding. This innovation laid the foundation for modern welding processes, which have continued to advance with the introduction of automation. Today, mechanical automation welding technology is revolutionizing the way industries approach metal fabrication.

One of the primary benefits of factory mechanical automation in welding is the significant increase in efficiency. Automated welding systems can operate continuously, reducing downtime and maximizing productivity. Unlike manual welding, which is subject to human fatigue and error, automated systems provide consistent quality and precision. This not only enhances the overall quality of the welds but also reduces the likelihood of defects, leading to lower material waste and cost savings.

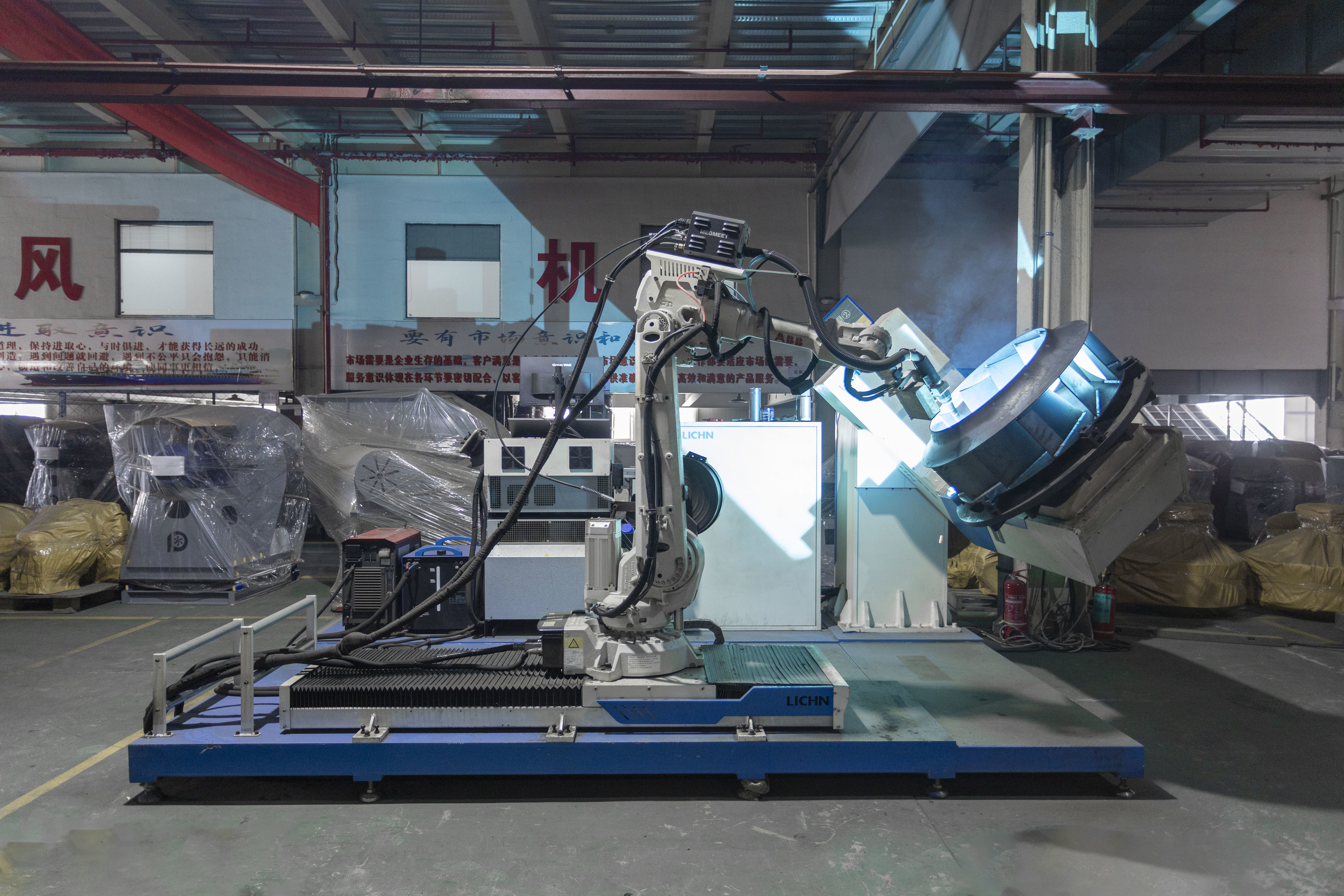

Moreover, the integration of robotics in welding processes allows for greater flexibility. Modern robotic welding systems can be programmed to perform a variety of tasks, from simple spot welding to complex multi-process operations. This adaptability enables manufacturers to respond quickly to changing market demands and production requirements. In addition, robotic systems can easily be reconfigured for different products, allowing factories to shift production lines with minimal disruption.

Safety is another critical aspect where mechanical automation welding technology shines. Traditional welding processes pose numerous risks to human workers, including exposure to harmful fumes, intense heat, and potential accidents. By automating these processes, factories can significantly reduce the risk of workplace injuries. Robots can operate in hazardous environments, performing tasks that would otherwise put human workers in danger. This shift not only protects employees but also fosters a safer overall working environment.

The implementation of advanced technologies such as artificial intelligence (AI) and machine learning is further enhancing the capabilities of automated welding systems. These technologies enable machines to learn from past performance and optimize their operations accordingly. For instance, AI can analyze data from previous welding jobs to identify the most efficient settings for current tasks, improving both speed and quality. As a result, manufacturers can achieve higher levels of precision and consistency, ultimately leading to better end products.

While the benefits of factory mechanical automation welding technology are clear, the transition to automated systems does present challenges. One significant concern is the initial investment required for automation equipment and training. Many small and medium-sized enterprises (SMEs) may find it difficult to allocate resources for such investments. However, the long-term savings and efficiency gains often outweigh the initial costs. Furthermore, as technology continues to evolve, the cost of automation is expected to decrease, making it more accessible to a broader range of businesses.

Another challenge is the potential impact on the workforce. As automation takes over repetitive and dangerous tasks, there is a growing concern about job displacement. However, rather than viewing automation as a threat, it should be seen as an opportunity for workforce evolution. With the right training and upskilling programs, workers can transition into more skilled roles that focus on overseeing automated systems, maintenance, and programming. This shift not only enhances job satisfaction but also contributes to a more skilled labor force capable of adapting to the demands of the modern manufacturing landscape.

Looking to the future, the potential for factory mechanical automation welding technology is immense. As industries continue to embrace Industry 4.0, the integration of the Internet of Things (IoT) and smart manufacturing practices will further enhance the capabilities of automated welding systems. Real-time data analysis and remote monitoring will enable manufacturers to optimize their processes continuously, ensuring maximum efficiency and quality.

In conclusion, factory mechanical automation welding technology is leading the wave of industrial welding in the new era. Its benefits, including increased efficiency, enhanced safety, and improved quality, position it as a vital component of modern manufacturing. While challenges remain, the potential for growth and innovation in this field is significant. As industries continue to evolve, embracing automation will be crucial for staying competitive in a rapidly changing global market. The future of welding is not just about joining materials; it is about harnessing technology to create a safer, more efficient, and more sustainable manufacturing landscape.

Tag:

Recommend News