Comprehensive analysis: How to operate stainless steel centrifugal fans to achieve better energy-saving effects?

Centrifugal fans are widely used in various industries for their efficiency in moving air and gases. Among the different materials used in their construction, stainless steel stands out due to its durability and resistance to corrosion. However, merely installing a stainless steel centrifugal fan is not enough to ensure optimal energy savings. Proper operation and maintenance are crucial for achieving the best performance and energy efficiency. This article provides a comprehensive analysis of how to operate stainless steel centrifugal fans effectively to achieve better energy-saving effects.

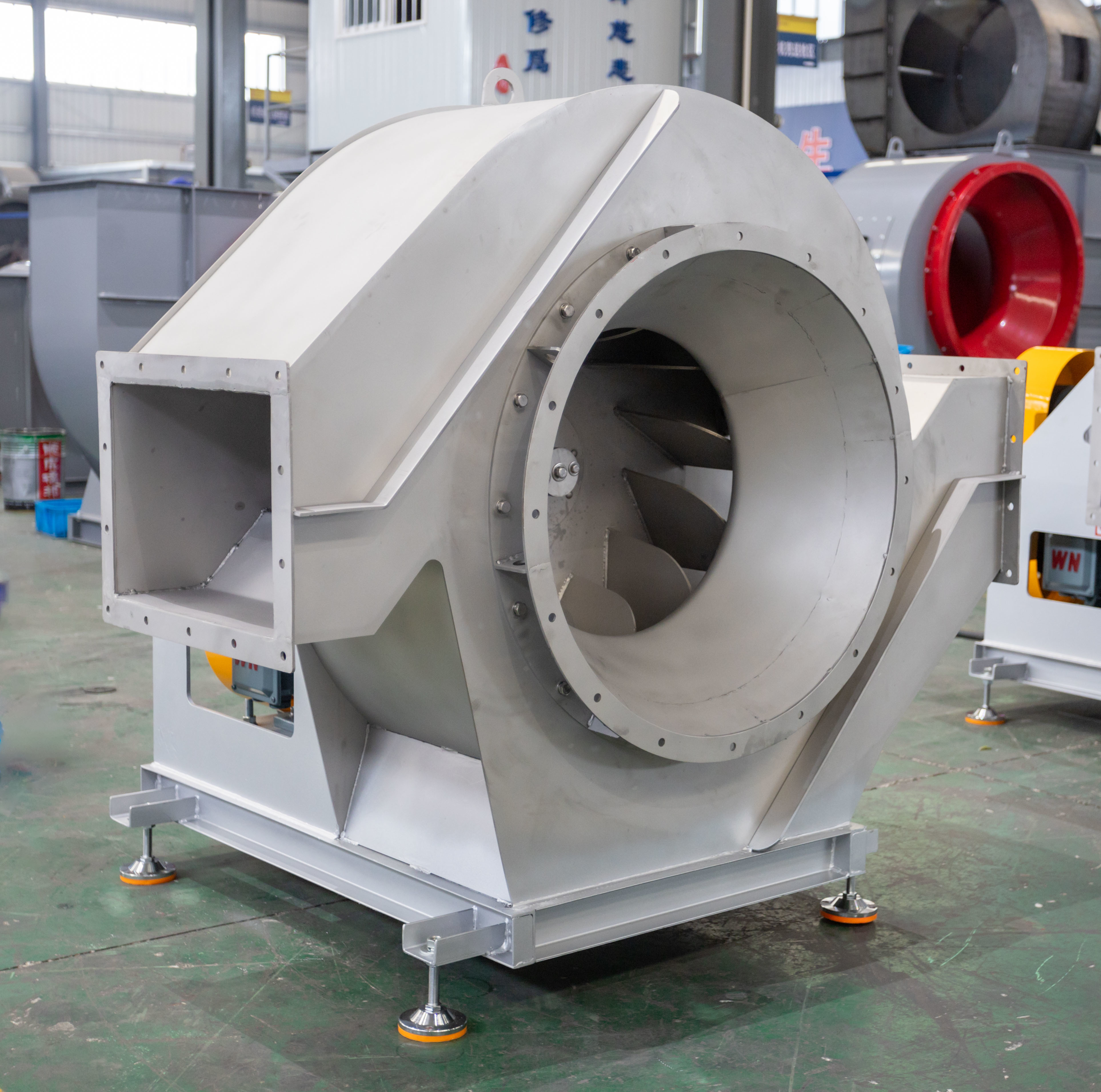

Understanding Centrifugal Fans

Before delving into operational strategies, it is essential to understand the basic working principles of centrifugal fans. These fans operate by converting rotational energy from a motor into airflow. The air enters the fan through the inlet and is accelerated outward by the impeller, which creates a pressure difference that moves the air through the system. The design of the fan, including blade shape and motor speed, plays a significant role in its efficiency and performance.

**Selecting the Right Fan for the Application**

One of the first steps in ensuring energy efficiency is selecting the appropriate fan for your specific application. Consider factors such as air volume requirements, pressure levels, and the nature of the gas being moved. A fan that is too large or too small for the application can lead to inefficiencies, increased energy consumption, and premature wear. By conducting a thorough analysis of the system's needs, operators can choose a fan that operates within its optimal range, reducing energy waste.

Optimal Fan Speed and Control

The speed at which a centrifugal fan operates directly affects its energy consumption. Operating at full speed all the time may not be necessary for many applications. Implementing variable frequency drives (VFDs) allows for better control of the fan speed, enabling operators to adjust the airflow according to demand. This not only helps in reducing energy consumption but also extends the lifespan of the fan by minimizing wear and tear.

Regular Maintenance and Inspection

To ensure that stainless steel centrifugal fans operate at peak efficiency, regular maintenance is crucial. Over time, dust and debris can accumulate on the blades, leading to reduced airflow and increased energy consumption. Routine inspections should include checking for any signs of wear, ensuring that the motor and bearings are lubricated, and confirming that there are no obstructions in the airflow path. A well-maintained fan will operate more efficiently, resulting in significant energy savings.

Optimizing Ductwork and System Design

The efficiency of a centrifugal fan is not solely dependent on the fan itself; the entire duct system plays a vital role in performance. Poorly designed ductwork can create unnecessary resistance, leading to higher energy consumption. Ensuring that ducts are properly sized, have smooth bends, and are free of obstructions can significantly enhance the overall efficiency of the system. Operators should also consider the placement of the fan within the system to minimize losses due to turbulence and resistance.

Monitoring Performance and Energy Consumption

Implementing a monitoring system to track the performance of stainless steel centrifugal fans can provide valuable insights into energy usage. By analyzing data on airflow, pressure, and energy consumption, operators can identify trends and make informed decisions about adjustments that may be needed. Monitoring can also help in detecting any anomalies that may indicate a drop in efficiency, allowing for timely maintenance interventions.

Training and Awareness for Operators

The human factor is often overlooked when discussing energy efficiency. Proper training for operators is essential to ensure they understand the operational parameters and best practices for running centrifugal fans. Educating staff on the importance of energy savings, as well as how to identify inefficiencies, can lead to more proactive management of the fan systems. A culture of awareness regarding energy consumption can result in significant long-term savings.

Utilizing Advanced Technologies

As technology advances, new tools and systems are becoming available that can further enhance the efficiency of centrifugal fans. Smart sensors, for example, can provide real-time data on fan performance and energy consumption, allowing for immediate adjustments to be made. Additionally, predictive maintenance technologies can forecast potential issues before they lead to significant energy losses. Investing in these technologies may require upfront costs but can lead to substantial savings in the long run.

Conclusion

In conclusion, operating stainless steel centrifugal fans for better energy-saving effects requires a multifaceted approach. From selecting the right fan for the application to implementing regular maintenance, optimizing system design, and utilizing advanced technologies, every aspect contributes to the overall efficiency of the fan. By prioritizing energy efficiency through careful operation and management practices, industries can not only reduce operational costs but also contribute to a more sustainable future. Emphasizing training and awareness among operators further enhances these efforts, ensuring that energy-saving practices are ingrained in the organizational culture. Ultimately, a comprehensive strategy will lead to significant improvements in energy efficiency and performance in centrifugal fan operations.

Tag:

Recommend News