Adjustment and optimization of dynamic balance of centrifugal fan impeller

Adjustment and Optimization of Dynamic Balance of Centrifugal Fan Impeller

Adjustment and Optimization of Dynamic Balance of Centrifugal Fan Impeller

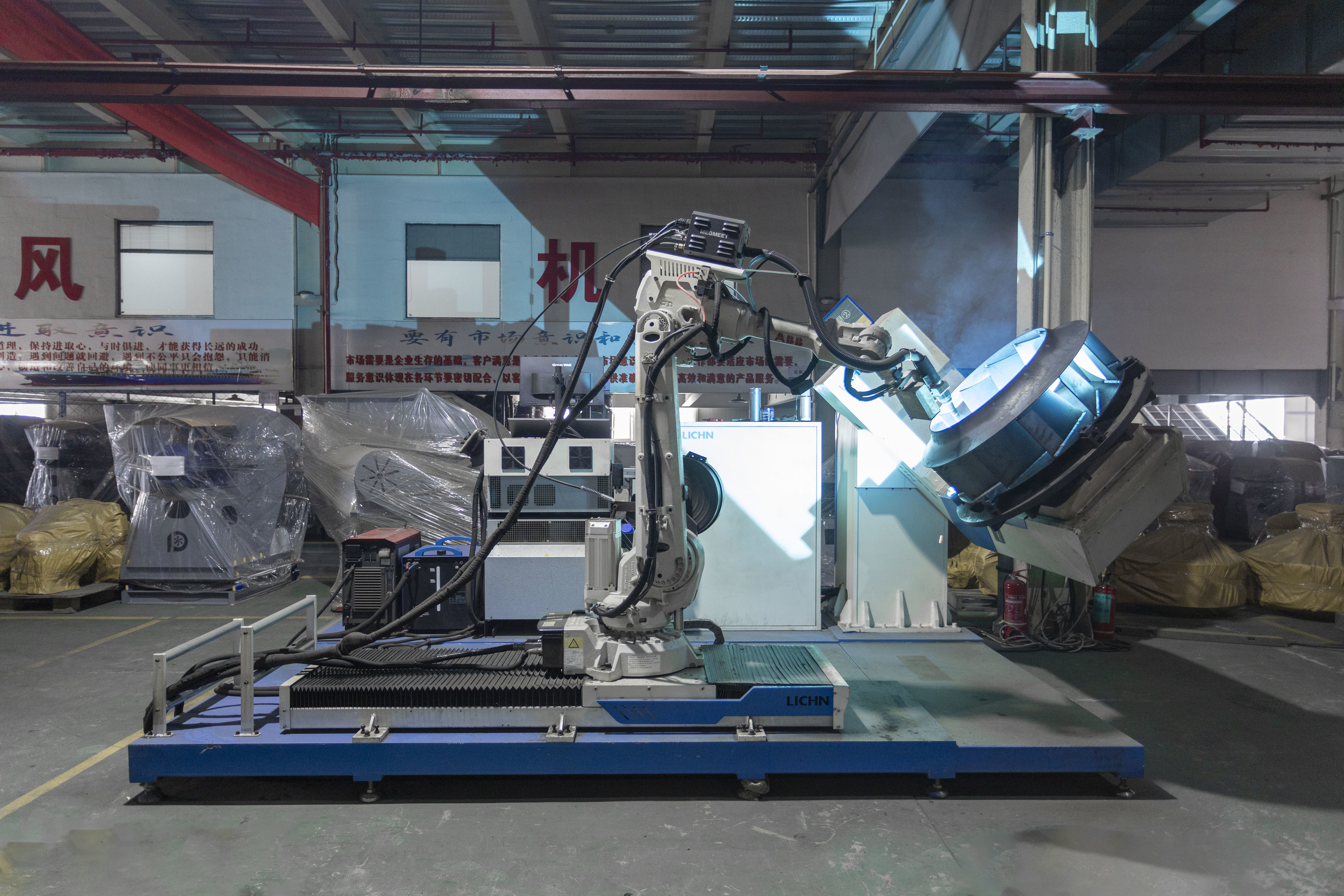

The centrifugal fan impeller plays a crucial role in various industrial applications, including HVAC systems, material handling, and dust collection. One of the key performance factors for these fans is the dynamic balance of the impeller. An imbalanced impeller can lead to excessive vibration, noise, and reduced efficiency, ultimately affecting the overall performance of the system. This article discusses the importance of dynamic balance in centrifugal fan impellers, the methods for adjustment and optimization, and the benefits of achieving a well-balanced impeller.

Dynamic balance refers to the condition where the mass distribution of the rotating component is uniform, allowing for smooth operation without excessive vibration. In centrifugal fans, an imbalanced impeller can cause vibrations that not only lead to mechanical wear and tear but also affect the surrounding equipment and structures. It can result in increased energy consumption, reduced airflow efficiency, and even catastrophic failures if left unaddressed. Therefore, ensuring the dynamic balance of the impeller is essential for optimal fan performance and longevity.

The first step in achieving a well-balanced impeller is to identify any imbalances present. This can be done through various measurement techniques, such as using vibration analysis tools or balancing machines. Vibration analysis involves measuring the amplitude and frequency of vibrations produced by the fan during operation. By analyzing these vibrations, engineers can determine the source of the imbalance and its severity. Balancing machines, on the other hand, can provide real-time feedback on the impeller's balance status, allowing for precise adjustments.

Once an imbalance has been identified, the next step is to make adjustments to the impeller. There are several methods for achieving this, including adding or removing mass from specific locations on the impeller. For instance, if the impeller is found to be heavy on one side, engineers may add counterweights to the opposite side to redistribute the mass. Alternatively, material can be removed from the heavier side to achieve a more uniform mass distribution. This process often requires iterative testing and adjustments until the desired balance is achieved.

Another effective method for optimizing the dynamic balance of centrifugal fan impellers is through design modifications. Engineers can consider various design aspects, such as the shape and material of the impeller, to enhance balance. For example, using lightweight materials can reduce the overall mass of the impeller, which can improve balance and reduce energy consumption. Additionally, optimizing the geometry of the impeller can help distribute mass more evenly, further reducing the risk of imbalance.

In some cases, dynamic balancing can be achieved through the use of advanced technologies such as computer-aided design (CAD) and computational fluid dynamics (CFD). These tools allow engineers to simulate the performance of the impeller under various operating conditions, helping to identify potential imbalance issues before physical testing. By using these technologies, engineers can make informed design decisions that enhance the dynamic balance of the impeller from the outset.

The benefits of achieving a well-balanced centrifugal fan impeller are significant. First and foremost, it leads to reduced vibrations, which can prolong the life of the fan and its associated components. This reduction in wear and tear translates to lower maintenance costs and fewer unexpected breakdowns. Additionally, a balanced impeller enhances airflow efficiency, allowing the fan to operate at optimal performance levels. This can result in energy savings and reduced operational costs, making it a win-win situation for businesses.

Moreover, achieving dynamic balance contributes to a quieter operation, which is particularly important in applications where noise levels must be minimized, such as in residential areas or sensitive environments. A well-balanced impeller also enhances the overall reliability of the fan system, ensuring consistent performance over time.

In conclusion, the adjustment and optimization of dynamic balance in centrifugal fan impellers are critical for ensuring efficient and reliable operation. By identifying imbalances through measurement techniques and making necessary adjustments or design modifications, engineers can achieve a well-balanced impeller that reduces vibrations, enhances efficiency, and prolongs the lifespan of the fan system. As industries continue to prioritize energy efficiency and reliability, the importance of dynamic balance in centrifugal fan impellers will only continue to grow. Businesses that invest in these practices will undoubtedly reap the benefits of improved performance and reduced operational costs.

Tag:

Recommend News