Comprehensive analysis of adjustment methods for centrifugal fans

Centrifugal fans are widely used in various industrial applications for ventilation, cooling, and material handling. Their efficiency and performance can be significantly influenced by the adjustment methods employed. This article provides a comprehensive analysis of the various adjustment methods available for centrifugal fans, discussing their principles, advantages, and potential drawbacks.

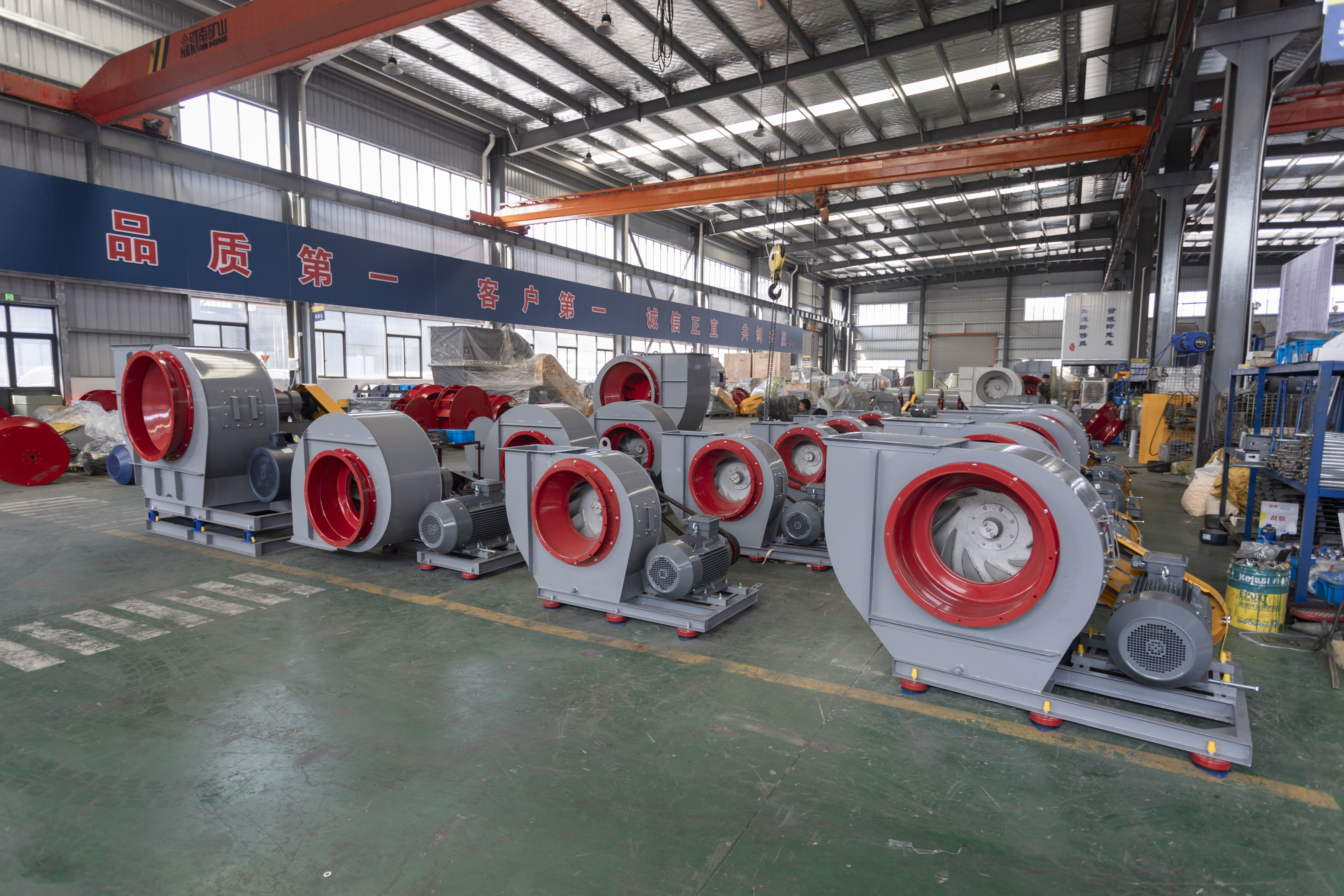

1. Introduction to Centrifugal Fans

Centrifugal fans, also known as blowers, operate on the principle of converting rotational energy into air movement. They are characterized by their impeller design, which draws air into the fan and expels it at a right angle to the intake. The performance of centrifugal fans is typically defined by parameters such as flow rate, pressure rise, and power consumption. To optimize these parameters for specific applications, various adjustment methods can be employed.

2. Types of Adjustment Methods

There are several adjustment methods available for centrifugal fans, including:

2.1. Varying Speed

2.1. Varying Speed

One of the most common methods for adjusting the performance of centrifugal fans is through varying the speed of the motor driving the fan. This can be achieved using variable frequency drives (VFDs) or by employing mechanical means such as pulleys and belts.

- Advantages: Varying speed allows for precise control over the flow rate and pressure, enabling the fan to operate efficiently under varying load conditions. It also helps in energy conservation, as the fan can be operated at lower speeds during periods of reduced demand.

- Drawbacks: The initial investment for VFDs can be high, and the complexity of the control systems may require skilled personnel for operation and maintenance.

2.2. Blade Pitch Adjustment

Another method for adjusting the performance of centrifugal fans is through blade pitch adjustment. This involves changing the angle of the blades relative to the airflow.

- Advantages: Blade pitch adjustment can significantly impact the fan's efficiency and performance. It allows for optimal operation across a range of conditions, making it suitable for applications with varying airflow requirements.

- Drawbacks: Mechanical systems for blade pitch adjustment can be complex and may require regular maintenance to ensure proper operation. Additionally, the adjustment process can be time-consuming.

2.3. Inlet Vane Control

Inlet vanes are devices installed at the inlet of the fan that can be adjusted to control the amount of air entering the fan.

- Advantages: This method provides a simple and effective way to control the flow rate and can improve the fan's efficiency at partial loads. Inlet vanes can also reduce noise levels by smoothing the airflow entering the fan.

- Drawbacks: The installation of inlet vanes may lead to increased pressure losses, which can affect overall system performance. Additionally, the adjustment mechanism may require regular inspection and maintenance.

2.4. Duct System Modifications

Adjustments to the duct system connected to the centrifugal fan can also influence its performance. This can include changing the diameter of ducts, adding or removing bends, and altering the length of the ductwork.

- Advantages: Optimizing the duct system can improve airflow efficiency and reduce energy consumption. This method can also help in balancing the system, ensuring that air is distributed evenly throughout the space.

- **Drawbacks**: Modifying duct systems can be costly and time-consuming. It may also require significant changes to existing infrastructure, which can lead to operational disruptions.

3. Energy Efficiency Considerations

When selecting an adjustment method for centrifugal fans, energy efficiency is a critical factor. Many of the adjustment methods discussed can lead to significant energy savings, particularly when coupled with proper system design and control strategies.

- For instance, using VFDs in conjunction with a well-designed duct system can optimize energy consumption, particularly in applications with variable airflow demands.

- Additionally, regular maintenance and performance monitoring can help identify inefficiencies and allow for timely adjustments to ensure optimal operation.

4. Conclusion

In conclusion, the selection of an appropriate adjustment method for centrifugal fans is crucial for optimizing performance and energy efficiency. Each method has its advantages and drawbacks, and the best choice will depend on the specific application, operational requirements, and budget considerations.

- As industries continue to focus on sustainability and energy conservation, understanding and implementing effective adjustment methods will play a vital role in enhancing the performance of centrifugal fans.

- Future developments in technology, such as advanced control systems and more efficient fan designs, will likely continue to improve the efficiency and adaptability of centrifugal fans in various applications.

By carefully considering the various adjustment methods and their implications, industries can ensure that their centrifugal fans operate at peak performance while minimizing energy consumption and operational costs.

Tag:

Recommend News