How to achieve energy-saving optimization of stainless steel centrifugal fans?

In today's industrial landscape, energy efficiency has become a critical concern for manufacturers and facility managers. Stainless steel centrifugal fans are widely used in various applications due to their durability and corrosion resistance. However, optimizing these fans for energy savings is essential not only for reducing operational costs but also for minimizing environmental impact. This article outlines effective strategies to achieve energy-saving optimization of stainless steel centrifugal fans.

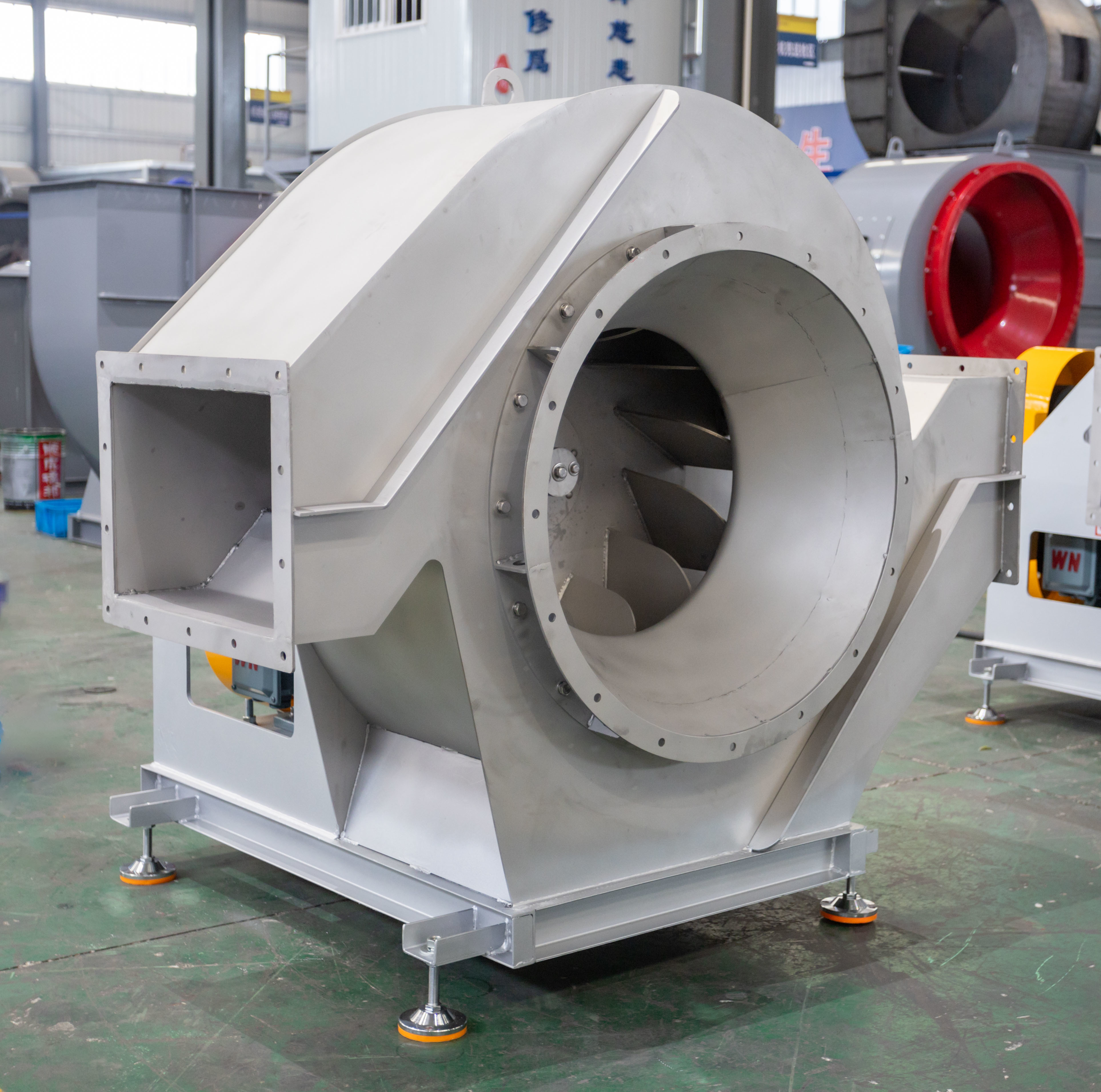

Understanding the Basics of Centrifugal Fans

Centrifugal fans operate by converting rotational energy from a motor into kinetic energy, which is then used to move air or gas. They are characterized by their impeller design, which creates a pressure difference that enables airflow. The efficiency of a centrifugal fan is influenced by several factors, including its design, motor efficiency, and operating conditions. Understanding these elements is crucial for implementing energy-saving measures.

1. Selecting the Right Fan Design

The first step in optimizing energy efficiency is selecting the right fan design for the specific application. Fans come in various configurations, such as backward-curved, forward-curved, and radial blades. Each design has its advantages and disadvantages regarding efficiency and performance.

Backward-curved fans, for instance, are known for their high efficiency and lower energy consumption at varying airflow rates. In contrast, forward-curved fans may be suitable for applications requiring high air volume at lower pressures. Therefore, conducting a thorough analysis of the application requirements and selecting the appropriate fan design can significantly impact energy savings.

2. Properly Sizing the Fan

Another critical factor in energy optimization is ensuring that the fan is appropriately sized for the application. An oversized fan can lead to unnecessary energy consumption, while an undersized fan may struggle to meet airflow demands, resulting in increased wear and tear.

Using fan selection software or consulting with a fan manufacturer can help determine the optimal size and capacity needed for specific operational conditions. Properly sized fans not only improve efficiency but also extend the lifespan of the equipment, leading to further energy savings.

3. Utilizing Variable Frequency Drives (VFDs)

Variable frequency drives (VFDs) are an effective solution for optimizing the energy consumption of stainless steel centrifugal fans. VFDs allow for precise control of the fan's speed, enabling it to adjust to varying airflow demands.

By matching the fan speed to the actual requirements, VFDs can reduce energy consumption significantly. For example, reducing the fan speed by just 20% can result in a 50% reduction in energy use. Implementing VFDs is particularly beneficial in applications with fluctuating airflow demands, such as HVAC systems and industrial processes.

4. Implementing Efficient Motor Technology

The efficiency of the motor driving the centrifugal fan is another crucial factor in overall energy consumption. Selecting high-efficiency motors, such as premium efficiency or inverter-duty motors, can lead to substantial energy savings.

Moreover, regular maintenance of the motor, including lubrication and alignment checks, can prevent energy losses due to friction and wear. Investing in energy-efficient motor technology and ensuring proper maintenance practices can enhance the overall efficiency of the fan system.

5. Conducting Regular Maintenance

Routine maintenance is essential for ensuring that stainless steel centrifugal fans operate at peak efficiency. Dust and debris accumulation can hinder airflow and increase energy consumption.

Regular inspections should include checking for worn-out components, ensuring proper lubrication, and cleaning the fan and ductwork. Implementing a scheduled maintenance program can prevent unexpected breakdowns and maintain optimal performance, leading to energy savings over time.

6. Monitoring System Performance

To achieve ongoing energy savings, it is vital to monitor the performance of stainless steel centrifugal fans continuously. Utilizing sensors and monitoring systems can provide real-time data on airflow, pressure, and energy consumption.

By analyzing this data, facility managers can identify inefficiencies and make informed decisions regarding operational adjustments. For instance, if a fan is consistently operating below its capacity, it may be an indication of an oversized unit or a need for maintenance. Regular performance monitoring allows for proactive measures to optimize energy use.

7. Considering System Design and Layout

The overall system design and layout can also influence the energy efficiency of centrifugal fans. Factors such as duct design, airflow obstructions, and the distance between the fan and the application can affect performance.

Minimizing bends, turns, and obstructions in ductwork can reduce resistance and improve airflow, leading to lower energy consumption. Additionally, ensuring that the fan is located as close to the application as possible can minimize energy losses associated with long duct runs.

Conclusion

Achieving energy-saving optimization of stainless steel centrifugal fans involves a multifaceted approach that includes selecting the right fan design, properly sizing the fan, utilizing VFDs, investing in efficient motor technology, conducting regular maintenance, monitoring performance, and considering system design. By implementing these strategies, organizations can significantly reduce energy consumption, lower operational costs, and contribute to a more sustainable industrial environment. In an era where energy efficiency is paramount, optimizing centrifugal fans is not just an option but a necessity for responsible and cost-effective operations.

Tag:

Recommend News